How to change the cutter head of the microtunnelling machine when there is a hard rock in between the drive...

It is not uncommon for microtunnelling contractors to arrive on site and find the ground conditions are different to the geotechnical information provided. This is problematic for most microtunnelling projects as most machines are not designed to allow easy access to the cutter head once an installation has started. So if you don’t have the right equipment and you encounter rock, project costs and time can increase. Microtunnelling, as a trenchless installation method, by nature is non-man entry, so contractors do not have the ability to get up to the cutter head physically in order to change the tooling. This...

Read More

Top benefits of pipe jacking

Pipe jacking is a trenchless pipeline installation method that has gained popularity as an alternative to open cut methods in urban areas where existing infrastructure needs to be navigated and disruption to residents needs to be minimised. Here, we look at the environmental, urban and safety benefits of pipe jacking, and why it should be considered over other methods of pipeline installation. What is pipe jacking? Pipe jacking is a non-disruptive method of installing pipes where the pipe is directly installed in a continuous length behind a machine while controlled excavation takes place at the face. The result is a...

Read More

Minimising disruptions and maximising accuracy with microtunnelling

In crowded urban areas, the installation of underground utilities can pose major disruption to the community and the surrounding environment. When considering environmental concerns and community impact, trenchless technologies such as microtunnelling can help mitigate concerns by minimising disruptions. It also benefits asset owners by reducing time costs and increasing accuracy. In the past, when considering the installation of underground utilities contractors didn’t have access to trenchless technologies, and therefore more disruptive methods of installation were used, such as open cut trenching. Microtunnelling now offers an alternative, sustainable solution for installing pipelines quickly, accurately and with minimal disruption. Considering the...

Read More

Five things to consider before starting a microtunnelling job

There are several things to consider before undertaking a microtunnelling installation that influence accuracy, downtime and costs. Here, Stuart Harrison, Managing Director at Edge Underground, looks at five critical considerations that need to be taken into account to achieve a successful installation. An accurate guidance system Without a highly accurate installation method, projects with tight tolerances are at risk of costly installation failures. When it comes to accuracy, microtunnelling is unrivalled in the industry as it utilises a laser guided system to achieve an accuracy of +/-25mm, with the Vermeer AXIS guided boring system commonly achieving +/-10mm accuracy on...

Read More

No room for error: microtunnelling vs HDD considerations

Trenchless technology has been quickly growing in popularity due to its vast environmental, cost and time benefits. When selecting which technique, such as microtunnelling or HDD, to use for a pipe installation there are differences that need to be considered. Here, we look at the types of considerations that should be made when selecting the right trenchless solution. Line of installation There are many practical considerations when choosing between microtunnelling and HDD for pipe installations. One of the main considerations is the line the pipe needs to take. Microtunnelling machines are built to install pipe in a straight-line from pit...

Read More

Why is microtunnelling ideal for water and sewer pipeline installations?

Unlike deep excavation, trenchless techniques such as microtunnelling bypass surface obstructions and have minimal impact on the surrounding environment. In the case of water and sewer pipeline installations, this has multiple benefits for the community and environment, and reduces risks during installation. Benefiting the community The impact of construction on the community is a key consideration when a pipeline installation method is chosen. Microtunnelling has become a popular choice as it causes minimal disruption, resulting in fewer community objections and making it more likely that projects can start without issue. Traditional installation methods that involve large trenches can disrupt the...

Read More

How has laser guided microtunnelling revolutionised the industry?

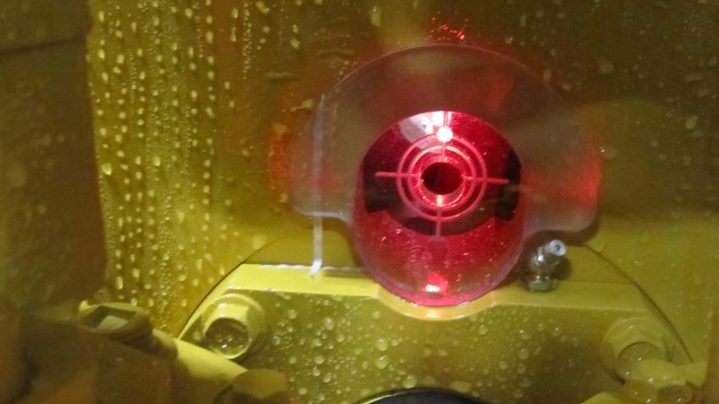

Being able to install pipelines on-grade is a must these days. This is especially the case in urban areas where a deviation from the route can result in damage to existing underground infrastructure. Microtunnelling is a trenchless method designed to achieve a high level of accuracy to prevent this. Laser guided machines, in particular, aid contractors in consistently installing pipelines on-grade. Guiding the way Microtunnelling is one of three main trenchless technologies for pipe installation that are pit-launched. Compared to the other main pit-launched technologies, thrust boring (also known as auger boring) and bed boring, microtunnelling offers the best accuracy....

Read More