How can strong principal and subcontractor partnerships increase the chance of success on a microtunnelling project?

Too often on construction sites – when unexpected situations occur or a different way of doing things to reduce risk and improve project outcomes are suggested – it can become a case of principal contractor versus subcontractor. When this occurs, it creates an environment that is not conducive to performance. In order to have a successful construction project, it is vital that there is a strong partnership between the principal contractor and the subcontractor. Communication is key to this; as unexpected conditions can increase risks of a project failing. Subcontractors need to be able to explain these risks as soon...

Read More

What pipe is most appropriate for different microtunnelling projects?

Pipe selection can make or break a project so to speak; the wrong pipe can make a project more difficult to complete, increase time and costs, or at worst, fail, while the right pipe will help reduce risk, enhance accuracy, reduce cost and improve the overall success of installation. But with a number of pipe materials available, how do you know which one is right for your application? This will come down to a number of factors – some of which have a greater impact than others – including ground conditions along the route of the pipeline, method of installation,...

Read More

Fighting against the elements: pre-planning for success in Townsville

Heading into the wet season in northern Queensland, Edge Underground was working against extreme heat and flash flooding on a microtunnelling project to complete three lines – with one under a major state highway. Fighting against the elements and upcoming holidays, planning played a major role in ensuring the success of the project, so that when the worst scenario occurred, Edge Underground could perform its best and get the job done on time. Edge Underground was subcontracted to complete three microtunnels in Townsville, partnering with Mendi Constructions, a well-known local business. The job required a 450DN, 500DN and 600DN concrete...

Read More

Donnybrook pipeline Stage 2: improved project outcomes with innovative solutions

A sudden change in ground conditions during a trenchless pipeline installation may require a rethink of how the project should proceed for the greatest chance of success. However, this can cause things to get complicated and costly when all parties involved have different ideas on how to proceed, and solicitors get involved. When presented with the possibility of such a situation occurring on a project site, Edge Underground collaborated with the other parties to come up with an alternative solution, saving the client time and money. In October 2019, Edge Underground was engaged by Diona for trenchless works on Yarra Valley...

Read More

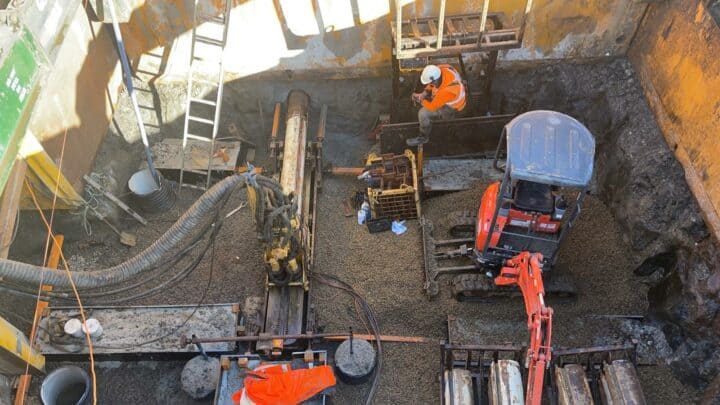

The advantages of vacuum excavation in microtunnelling projects

Vacuum excavation is a key method to help contractors maintain a safe, environmentally friendly, and compact microtunnelling site. This method reduces worksite size by sending excavated material straight from the pit to the tank, leaving the pit clear and the site clean, and eliminating the need for multiple trucks or loaders. Vacuum excavation in microtunnelling has many benefits – from safety, to environmental, to keeping a work site compact. This method sends excavated spoil straight to the tank, with the displaced spoil vacuumed out through a hollow section in the drill head and subsequent drill casing, transporting it to a...

Read More

Edge Underground: bringing innovation to microtunnelling

Since it was established in 2010, Edge Underground has been at the forefront of the Australian microtunnelling industry, pushing its boundaries, improving equipment and finding ways to complete some of the most challenging projects that no one else will take on. Edge Underground was founded by Managing Director, Stuart Harrision, a well-known figure in the Australian and international microtunnelling industry as a trenchless expert, pioneer of innovation and the inventor of the AXIS laser guided boring system. “When I first developed the AXIS in the early 2000s, it was because there was a gap in the industry for equipment that...

Read More

Overcoming the limitations of the microtunnelling industry

Compared to the traditional open cut method of pipeline installation, trenchless methods are still in their infancy, having only started to be developed around the 1970s. While trenchless methods have gained popularity in recent decades due to their reduced site footprint and ability to install under existing infrastructure and environmental formations, they are also an evolving technology with improvements still being made. Edge Underground is at the forefront of this evolution, helping the industry overcome its limitations through improved microtunnelling equipment and practices. Stuart Harrison, Managing Director at Edge Underground, said since first being developed over 50 years ago, microtunnelling...

Read More