When it comes to installing pipelines close to buildings, maintaining the stability of the structure is a major consideration. Microtunnelling is a trenchless solution that reduces the impact on the ground surrounding the installation, making it ideal for use in installations close to buildings and critical underground infrastructure.

In 2016, Edge Underground was called in to take over a project from another contractor to install an 88mm, 315 HDPE sewer pipe at a school in Mango Hill, north of Brisbane.

Stuart Harrison, Managing Director at Edge Underground, said the pipe needed to be installed right next to the school at a depth of around four and a half meters.

“To excavate four and a half meters deep right next to a building can be dangerous as it places a lot of questions on the stability of the structure. This was compounded by the fact that the ground was of fairly low load bearing capacity, making it questionable to work with,” Mr Harrison said.

“The pipe also had to be installed on grade as it needed to run next to an existing stormwater drain so there was no room for error.”

Before taking over the project, Edge had previously spoken to the client about price, as well as the possible risks associated with the job. Initially, a cheaper contractor offering a directional drilling solution was chosen. However once drilling started, the contractor encountered problems achieving grade.

“While the directional drill wasn’t truly accurate enough at that point, the contractor still tried to ream and install the pipe. But once they started investigating they realised that the pipe was going in on all the wrong angles and everything was an absolute mess,” Mr Harrison said.

“So they pushed out, and left a messy hole in the ground that we then got called in to fix. The complication with this was that we were not only fighting against what was already difficult conditions, we were also fighting against what the previous contractor had done. The difficulty in that was trying to understand the extent of the damage that had already been done.”

Assessing the damage

“In the past, pilot lines were predominantly installed via a displacement method. For this method to be successful, the ground being tunnelled through must be displaced and as the ground is often changing, displacement is often not possible,” Mr Harrison said.

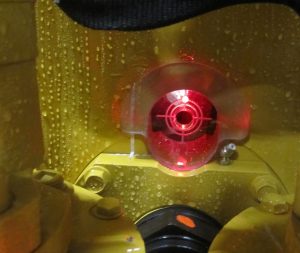

“Unlike traditional methods, the Vermeer AXIS system extracts the ground being tunnelled through rather than displacing it. It is designed to cut and extract the ground as it proceeds, and in doing so has little to no influence on the ground directly surrounding the installation.”

The AXIS system also utilises a vacuum extraction method that provides continued support to the ground by using a pipe jack system approach.

“We were told that they’d treated the ground, that it had been filled with grout and that we wouldn’t have any problems, and then we went in and started doing our pilot shot and established that they hadn’t been successful in grouting,” Mr Harrison said.

“There were massive voids left in the ground which could have caused problems, but because we’ve got the Vermeer AXIS guided boring system, we can go to a point, trip out, and grout as needed, all without needing to excavate.”

Mr Harrison said once Edge was fully aware of the ground conditions it was able to grout properly and finish the job within tolerances.

“As soon as we were able to get the ground into a semi-reasonable condition, we were able to install the line. When we’re doing extra works such as this, I think contractors think if they don’t say anything, then maybe they won’t have to pay for those works,” Mr Harrison said.

“Everyone was very happy with the end result. There was time in the middle that cost everyone money, which was due to the lack of transparency and the initial choice to go with the cheapest option.

“The reality is you’re better off allowing for all the work to be done up front, rather than half doing a job and realising that there are problems.”