Being able to install pipelines on-grade is a must these days. This is especially the case in urban areas where a deviation from the route can result in damage to existing underground infrastructure. Microtunnelling is a trenchless method designed to achieve a high level of accuracy to prevent this. Laser guided machines, in particular, aid contractors in consistently installing pipelines on-grade.

Guiding the way

Microtunnelling is one of three main trenchless technologies for pipe installation that are pit-launched. Compared to the other main pit-launched technologies, thrust boring (also known as auger boring) and bed boring, microtunnelling offers the best accuracy.

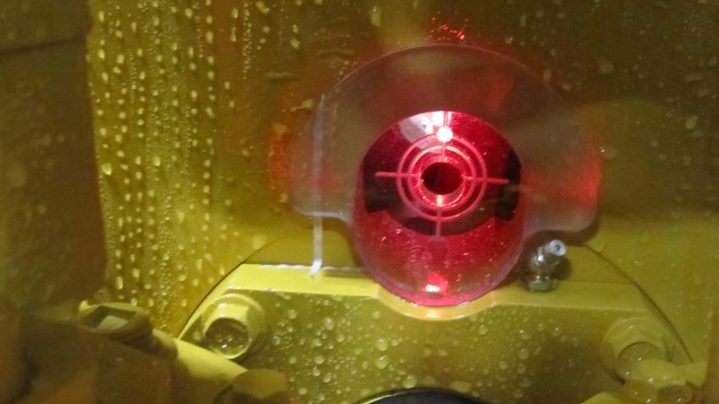

The reason that microtunnelling is seen as the most accurate pit-launched installation technique is because a high end laser guidance system is used to position the target with live monitoring. allowing the operator to watch what is happening during the installation and make hydraulic steering corrections as needed.

Measured from the design line, microtunnelling machines are able to install pipelines with accuracy of +/-10mm commonly achieved, allowing contractors to precisely install gravity pipelines within a tight tolerance.

This is different to thrust boring machines, which have traditionally been unguided. For machines without guidance systems, manufacturers state an accuracy of one per cent. To put that in perspective, over an installation distance of 100m, a typical result is a less than one metre of deviation from the target end point.

Bed boring is also traditionally an unguided technology used for short installations up to 25m. The accuracy of such installations depends upon the accuracy of setup, consistency of the ground and the individual operator’s feel for drilling. However, greater accuracy over longer distances has been achieved by combining pit-launched HDD and bed borers.

The keyhole factor

Laser guided systems have also allowed for the development of keyhole installations, where a pipe is installed via small vertical shafts, leaving everything in between undisturbed. Extreme accuracy is required for such installations due to the size of the shaft.

For example, if you were working from a four metre internal diameter shaft, you need to allow 500mm to set up the laser, so you’re left with less than 3.5m to establish a perfect line. If there is any error in the line, this will be multiplied over the length of the installation and the error will only be realised on the breakthrough at the reception shaft.

As the laser guidance system is monitored by a camera at all times, the contractor can see the trajectory of the drill head at all times, and can make steering corrections to ensure the drill is on course.

Keyhole installations also provide further benefits due to the reduced site footprint. As only entry and exit pits need to be excavated, and by only coring out the minimum amount of ground required to install a pipe, disruption to the ground is kept to a minimum and the impact to the surrounding environment, flora and fauna is greatly reduced.

Furthermore, the Vermeer AXIS guided boring system, a tool for precision on-grade microtunnelling installations, has been proven to have low carbon emissions.

During a project in the US which used the AXIS system, Dr Sam Ariaratnam and his team at Arizona State University did an emissions study utilising the ‘E Calc’ emissions calculator. The study compared the results to alternative methods, with the AXIS system conclusively presenting the least emissions of the methods.

Increased productivity

While the increased accuracy provided by laser guided machines has been a great benefit, many microtunnelling machines tend to be cumbersome and time consuming to work with, lacking the productivity to compete with open-cut methods.

The Vermeer AXIS guided boring system was designed to fill this gap in the market so that contractors can install pipelines accurately while also getting the job done quickly.

It is also versatile so it can meet a wide range of product pipe, sizing specifications, and other jobsite requirements.

This combination gives the on-grade accuracy and high efficiency customers demand while minimising restoration and installation costs.